Dry Milling Machine

E5

- Features

- The innovative solution for dry processing in the practice and the laboratory

- Mills almost all materials up to CoCr sintered metals in 98 mm disc format

- C-holder enables 90° machining of anterior teeth

- The first 5-axis milling machine without compressed air thanks to airtool

5 Axes|1 Disc|17 Tools

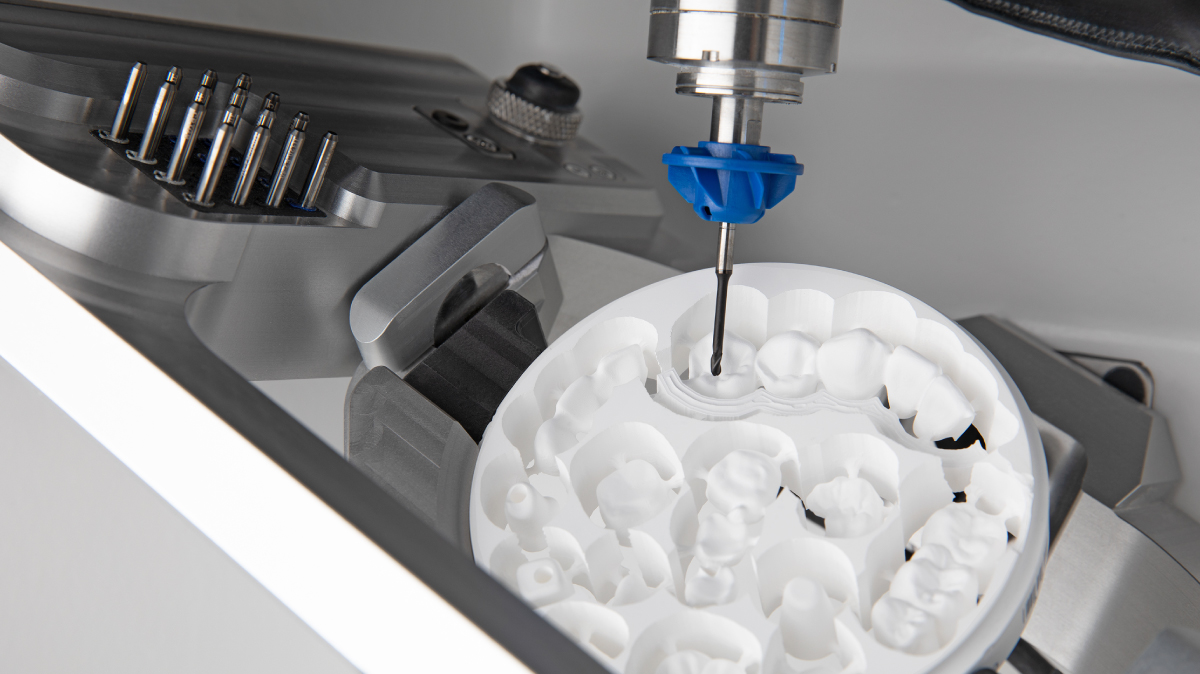

No compressed air needed – due to airtool

One great innovation of the E5 is that it uses no compressed air: The E5 requires neither an external compressed air connection nor an integrated compressor, which is possible with our patent-pending airtool.

The turbine blades on the airtool use the high speeds of the high-frequency spindle to generate a powerful air flow which keeps the workpiece free from dust and chippings. These are removed by suction.

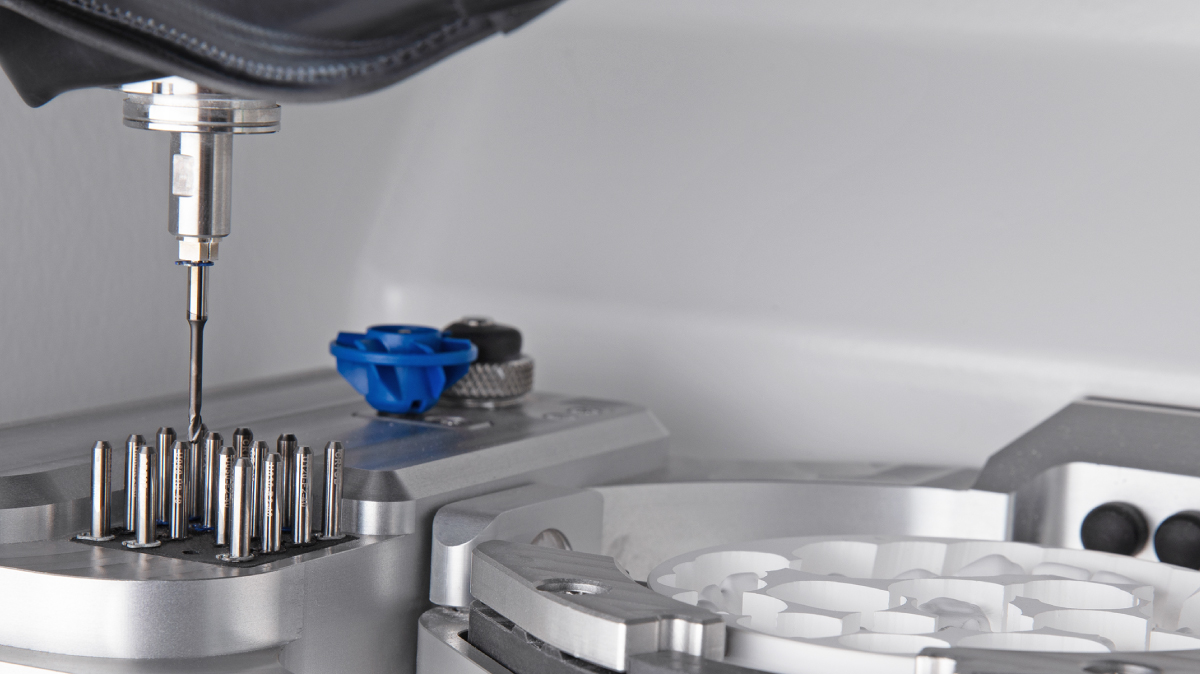

Automatic tool changer for 16 standard tools plus an airtool

Despite its compact design, the E5 offers a generous working chamber with plenty of space in which to clamp the workpieces or load the automatic tool changer.

Maximum freedom

The E5 not only allows you to machine discs; you can use the appropriate holder to process up to 6 blocks of different sizes with minimal effort.

Material, manufacturer, indication

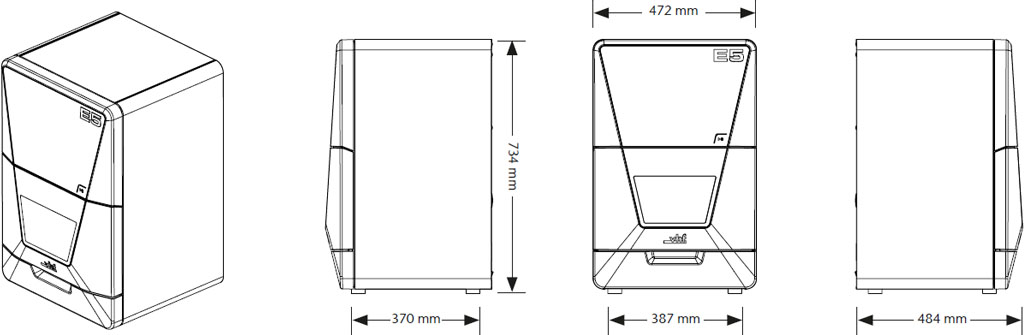

| Technical Specifications | |

|---|---|

| Dimension | 472 × 484 × 734 mm with closed door · 472 × 567 × 734 mm with open door |

| Weight | 47kg |

| Materials |

Composites, plastics/wax, zirconia, CoCr sintered metals |

| Number of Axes | 5 Axes |

| Fileds of application | Dry |

| Repetition accuracy | ±0.003mm |

| Spindle | High-frequency spindle,speed up to 60,000 rpm |

| Rotary axis B-axis | Backlash-free tension shaft gear with highest angular accuracy · rotation angle: ± 35° |

| Automation | Tool magazine for 16 tools plus one airtool |