Digital Health

Dry Milling Machine

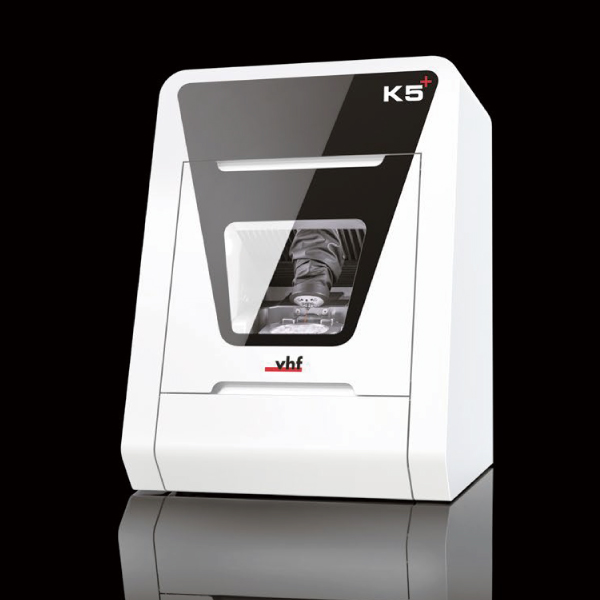

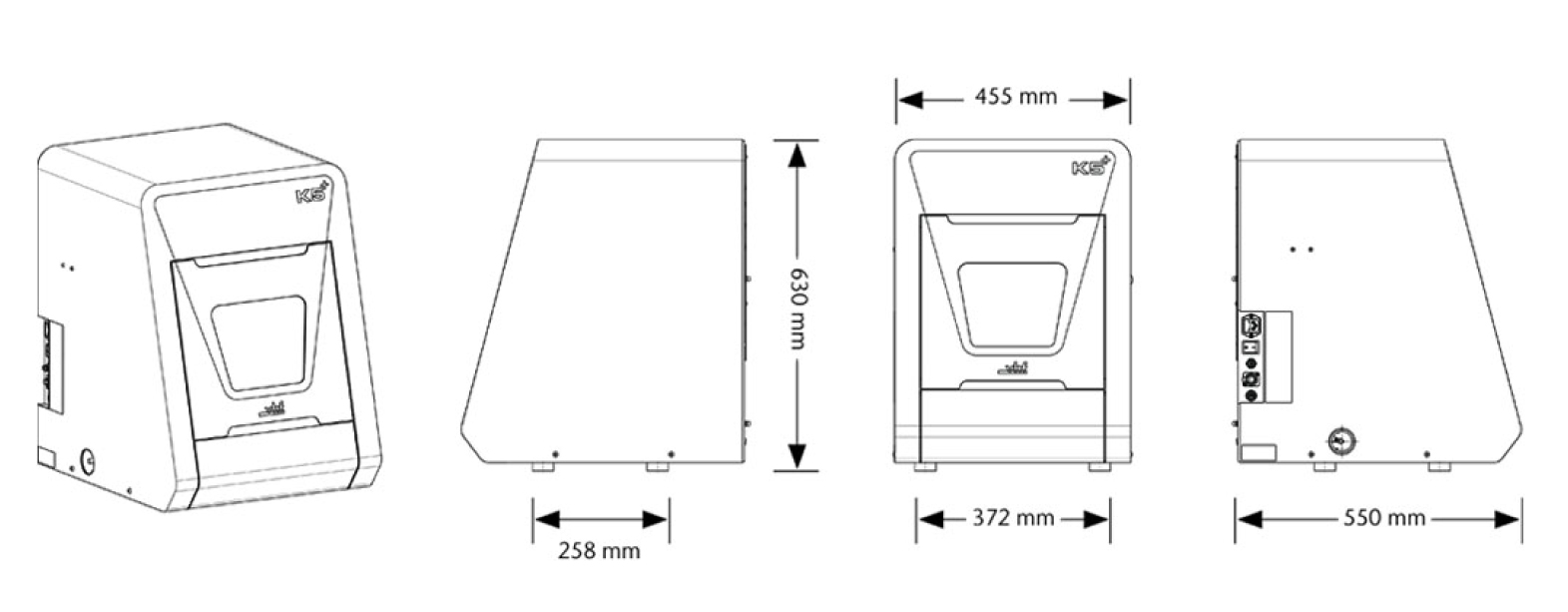

K5+

- Features

- Your top performer in the laboratory for convenient dry processing of blocks and discs.

- Mills the hardest materials including CoCr – ideal for metalworking thanks to the powerful spindle

- Fixes discs up to 40 mm thick – important for monolithic full dentures

- Ionizer against static charge and unsurpassed fast blank fixation thanks to directdisc technology

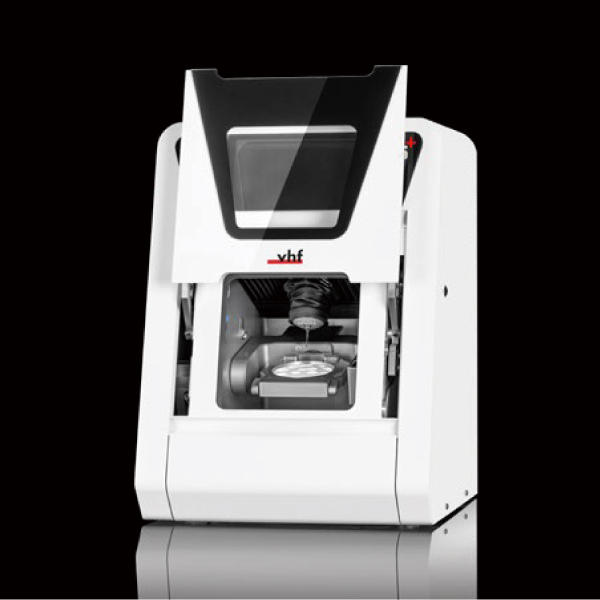

5 Axes|1 Disc|16 Tools

Quick start

Revolutionary technologies such as directdisc Technology for one-handed and tool-free blank clamping and an integrated ionizer, which largely neutralizes the static charge of plastic chips such as PMMA and thus considerably reduces the cleaning effort, help you to achieve this.

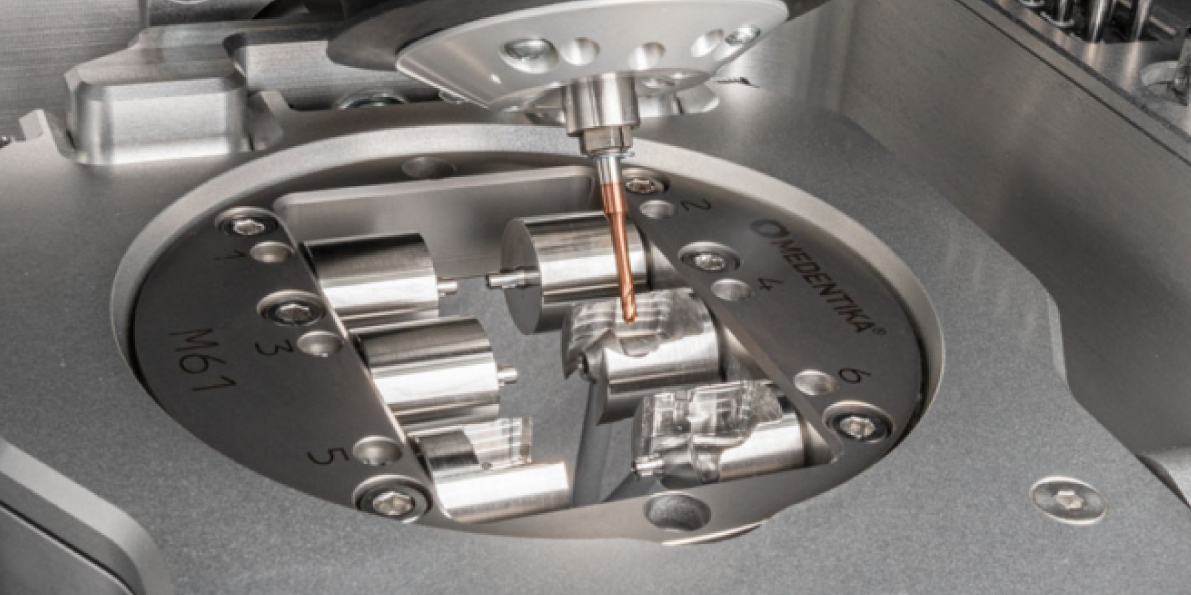

CoCr prefab abutments

You can also easily produce prefab abutments made of CoCr and block materials with the right holders.

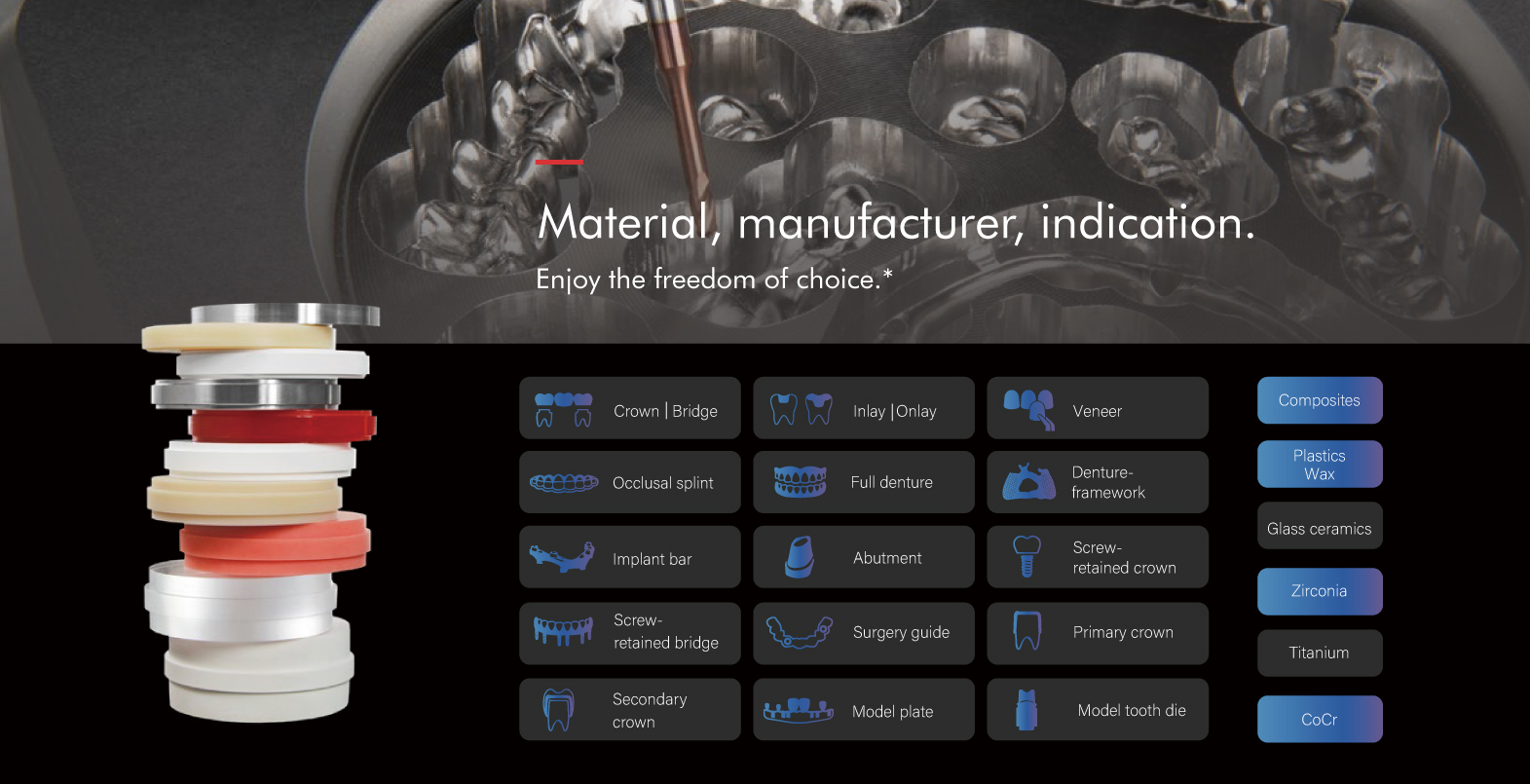

Discs up to a thickness of 40 mm

The K5+ processes discs up to a thickness of 40 mm. An ionizer neutralizes the charge of plastic chips.

| Technical Specifications | |

|---|---|

| Dimension | 450 × 545 × 630 mm with closed door · 450 × 695 × 680 mm with open door |

| Weight | 91kg |

| Materials | Plastic materials, wax, zirconia, composites, CoCr, model plaster • Blanks, height 10-40 mm (CoCr up to 18 mm), diameter 98.5 mm • Blocks up to 45 × 20 × 20 mm |

| Number of Axes | 5 Axes |

| Fileds of application | Dry |

| Repetition accuracy | ±0.003mm |

| Spindle | High-frequency spindle,speed up to 60,000 rpm |

| Rotary axis B-axis | Backlash-free tension shaft gear with highest angular accuracy · rotation angle: ± 35° |

| Camera system | Integrated in the working chamber for easy remote support and possibility of internal recording |

| Automation | Tool magazine for 16 tools |