Digital Health

Wet Milling Machine

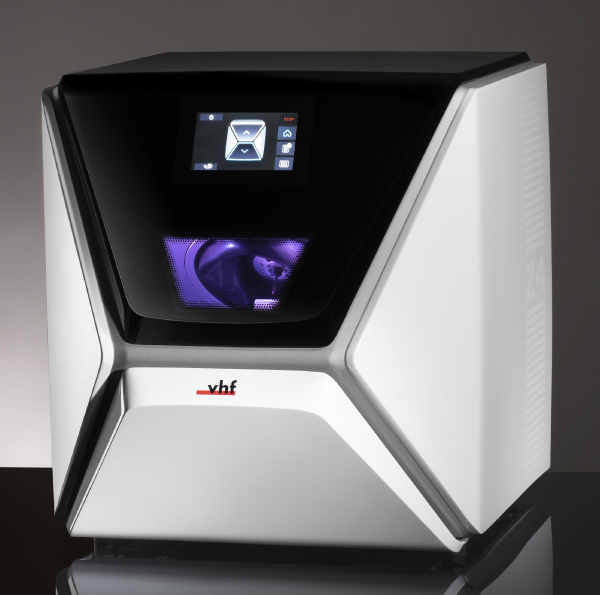

Z4

- Features

- Pure Water Precision Milling Technology

- High-Speed Spindle for Rapid Production

- 3 µm Repetition Accuracy

- Direct Milling for screw retained crowns

- Built-in Computer and Air Compressor for an all-in-one, hassle-free setup

4 Axes|1 Block|6 Tools

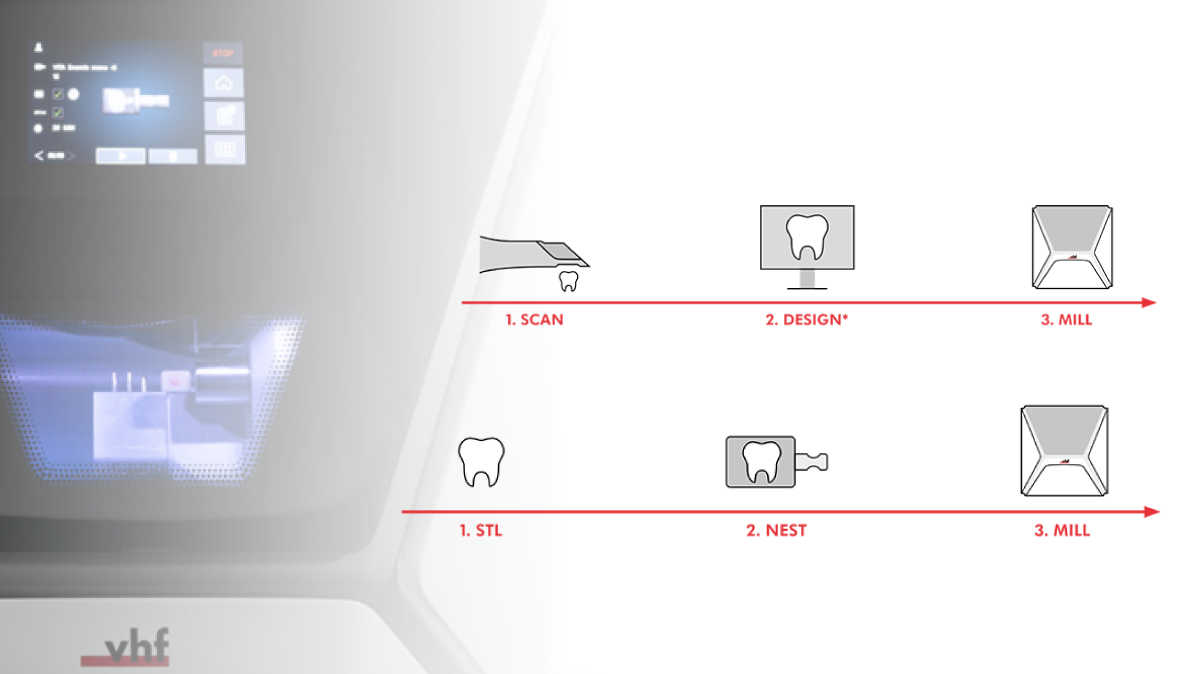

Integrated workflow with 3Shape, exocad

Everything in your practice: scanning, designing, milling in one smooth workflow.

Screw-access channels in highest quality

A scientific study at the University of Washington proved that using the Z4, users can drill screw-access channels for hybrid implant restorations into ceramic blocks with no signif-icant difference in flexural strength compared to factory-fabricated materials, known as meso blocks.

These blocks are significantly more expensive, and the laboratory design method requires a more sophisticated CAD process. Thus, processing standard blocks with the Z4 means less cost for material and less material inventory necessary.

Material, Manufacturer, Indication

| Technical Data | |

|---|---|

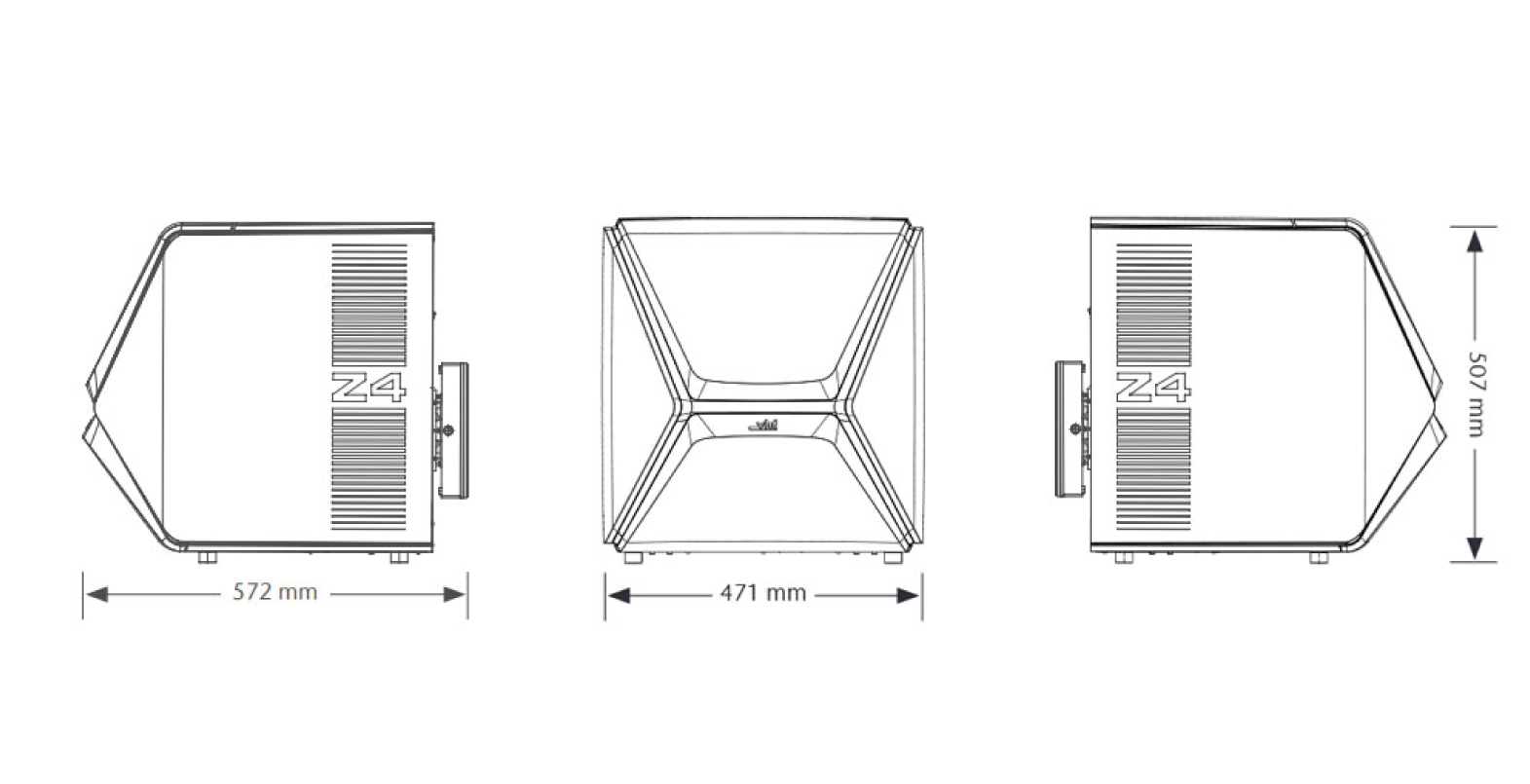

| Dimensions(W/D/H) | 471 × 522 × 507 mm with closed door · 471 × 737 × 608 mm with open door |

| Weight | 66kg |

| Materials | Composites, plastics/wax, glass ceramics, zirconia – Blocks up to 45 × 20 × 20 mm |

| Number of Axes | 4 |

| Fileds of application | Wet |

| Repetition accuracy | ±0.003mm |

| Spindle | High-frequency spindle,speed up to 100,000 rpm |

| Automation | Tool change:Tool magazine for 6 tools, removable |

| Camera system | Integrated in the working chamber for easy remote support and possibility of internal recording |

| Display | Capacitive 5-inch touchscreen display fully integrated into the front flap for local operation of the machine. |